GGD AC Low Voltage Distribution Cabinet

Short Description:

GGD type AC low-voltage distribution cabinet is suitable for power users such as power plants, substations, factories and mining enterprises, with AC 50Hz, rated working voltage of 380V, and rated working current up to 3150A

The power distribution system is used for the conversion, distribution, and control of electrical energy for power, lighting, and distribution equipment.

Product details

Product overview:

GGD type AC low-voltage distribution cabinet is suitable for power users such as power plants, substations, factories and mining enterprises, with AC 50Hz, rated working voltage of 380V, and rated working current up to 3150A

The power distribution system is used for the conversion, distribution, and control of electrical energy for power, lighting, and distribution equipment.

GGD type AC low-voltage distribution cabinet is a new type of low-voltage distribution cabinet designed based on the requirements of the competent authorities of the Ministry of Energy, power users, and design departments, in accordance with the principles of safety, economy, rationality, and reliability. The product has the characteristics of high breaking capacity, good dynamic and thermal stability, flexible electrical scheme, convenient combination, series, strong practicality, novel structure, and high protection level. It can be used as a replacement product for low-voltage switchgear.

GGD type AC low-voltage distribution cabinet complies with standards such as IEC 439 "Low voltage switchgear and control equipment" and GB 7251 "Low voltage switchgear".

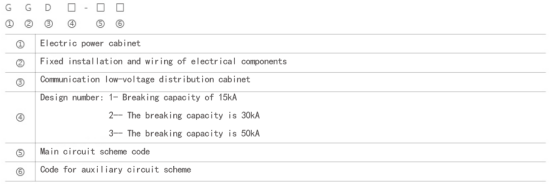

Model and meaning:

Usage conditions:

□ Environmental temperature: not exceeding 50% at a maximum temperature of+40 ℃, and allowing for higher relative humidity at lower temperatures. (For example, 90% at+20 ℃) should take into account the possibility of occasional condensation due to temperature changes;

□ During equipment installation, the inclination with respect to the vertical plane shall not exceed 5%,

□ The equipment should be installed in a place without severe vibration and impact, as well as in a place where electrical components are not susceptible to corrosion.

Note: If ordering this product exceeds the above conditions, please consult with our company.

Electrical performance:

1. Main circuit scheme

◆The main circuit design of GGD cabinet includes 129 schemes and a total of 298 specifications (excluding schemes and specifications derived from functional changes of auxiliary circuits and changes in control voltage)

Among them: 49 schemes and 123 specifications of GGD1 type

GGD2 model with 53 schemes and 107 specifications

GGD3 model with 27 schemes and 68 specifications

◆The main circuit scheme was selected based on the opinions of the design and usage departments, and additional schemes were added to meet the needs of the power plant. Rated current up to 3150A, suitable for distribution transformers of 2000KVA and below. In addition, GGJ1 and GGJ2 capacitor compensation cabinets were designed to meet the needs of reactive power compensation, with 4 main circuit schemes and a total of 12 specifications.

2. Auxiliary circuit scheme

The design of auxiliary circuit is divided into two parts: power supply scheme and power plant scheme. There is enough space in GGD cabinet to install secondary components. At the same time, a special LMZ3D current transformer has been developed to meet the needs of power plants and special users when attaching relay protection.

3. Main busbar

Considering the price ratio and the feasibility of replacing copper with aluminum, single aluminum busbar can be used when the rated current is 1500A or below, and double copper busbar can be used when the rated current is greater than 1500A. The manufacturer shall manufacture a prototype according to this regulation and pass the type test. Of course, the manufacturer can also replace the aluminum busbar with copper busbar of the same current carrying capacity according to the user's requirements. The overlapping surfaces of the busbar are treated with tin coating technology.

4. Selection of electrical components

GGD cabinets mainly use advanced electrical components that can be mass-produced domestically. At the same time, based on the principles of economy and rationality, some available old products such as DZ10D and DZ20 are retained while fully considering feasibility, and obsolete products are not selected.

The HD13BX and HS13BX rotary operated knife switches are specialized components designed to meet the unique structural needs of GGD cabinets. They change the operating mode of the mechanism and retain the advantages of old products, making them a practical new type of electrical component.

When the design department selects new electrical components with better performance and more advanced technology according to user needs, the GGD cabinet has good installation flexibility and generally does not cause manufacturing and installation difficulties due to updating electrical components.

To further improve the dynamic stability of the main circuit, a ZM type combined busbar clamp and insulation support for GGD cabinet were designed. The busbar clamp is made of high-strength and high flame retardant PPO alloy material thermoplastic molding, with high insulation strength, good self extinguishing performance, and unique structure. It can be easily

combined into a single busbar clamp or a double busbar clamp by adjusting the block type spacing blocks. The insulation support is a simple molded structure with low cost and high strength, which solves the problem of insufficient creepage distance in old products.

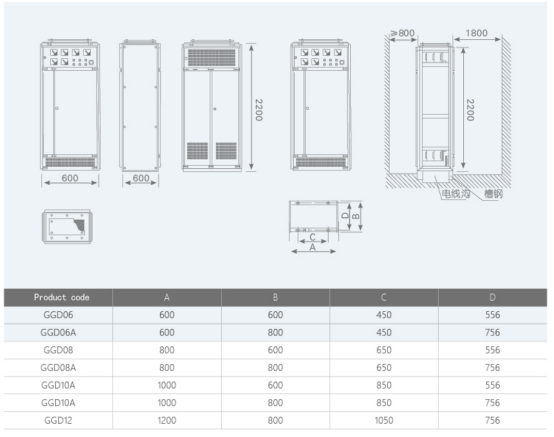

Mounting Dimension: